#CDRSP Researchers have been working with the ALBA Synchrotron Light Source in Barcelona since it opened to users in 2012. The Alba Synchrotron Light Source is the largest research infrastructure in Spain which houses a 3rd generation 3GeV synchrotron facility. ALBA contains a complex of electron accelerators that reach an energy of 3 GeV and emit synchrotron light, covering a wide range of photon energies, from soft X-rays of a few eV to hard X-rays of 70 keV. #CDRSP researchers have used principally hard x-rays to evaluate the molecular organisation of polymeric materials at the nanoscale initially on 3D printed scaffolds for tissue engineering. In 2018, the #CDRSP Team performed pioneering operando x-ray scattering during 3D printing in order to develop an understanding of the process of extruder-based 3D printing. This led to the concept of morphology mapping. In 2021/22 they carried out operando x-ray scattering measurements during biaxial deformation, to fully understand the process of crystallisation in natural rubber which is critical to its fatigue properties.

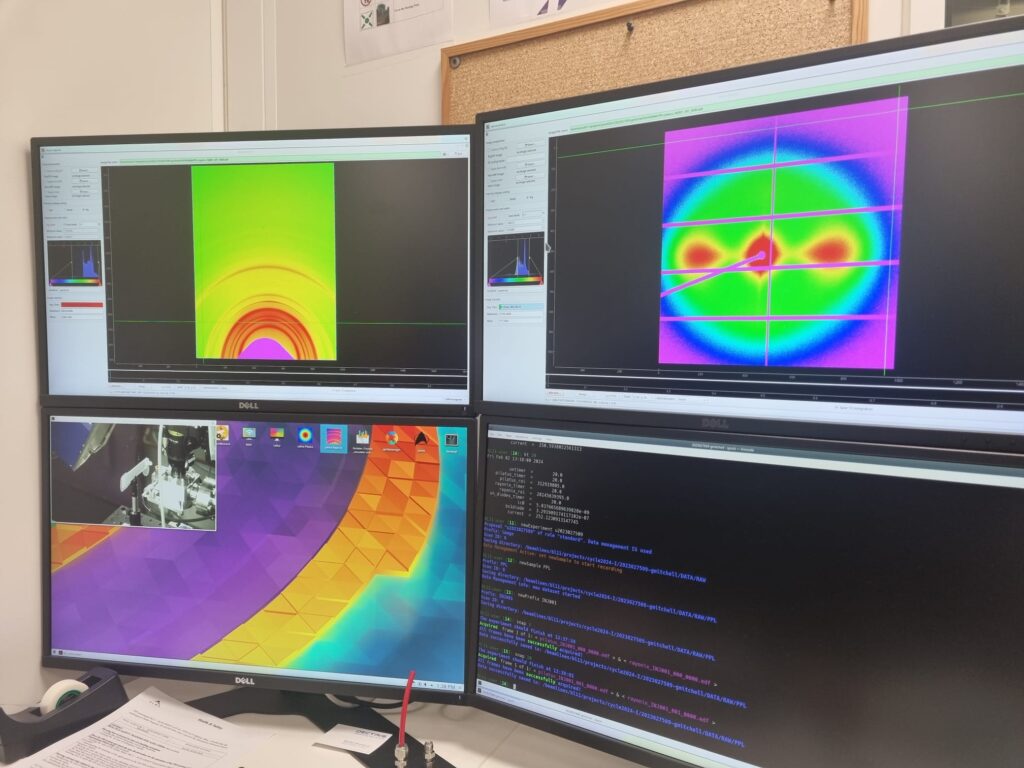

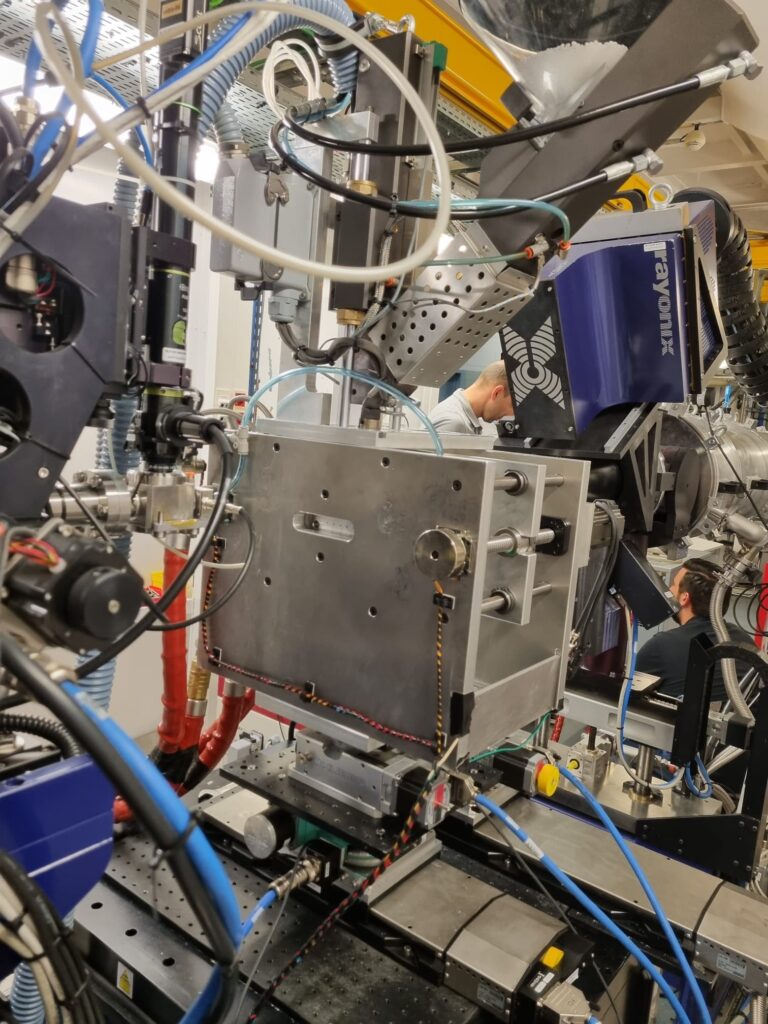

In 2022, the #CDRSP Team performed the world’s first operando x-ray scattering measurements during industrially relevant injection moulding of thermoplastics. Until these experiments the processes which accompany the transformation of a molten polymer injected into a mould cavity to a solid have only been studied through post-processing investigation. The experiments performed by the #CDRSP team allow researchers to follow in real time the development of the preferred molecular orientation and the accompanying semi-crystalline morphology. Observing the first few seconds of injection moulding greatly improves our understanding of the process and its relationship to properties and design. In 2023, the team performed join experiments with a team from Maastricht University on bioplastics. In the last two years, the #CDRSP team has enhanced the operando equipment so that in 2024, they were able to observe the first few milli-seconds of injection moulding. The team are using this one-of-a-king experimental system to improve the injection moulding of green materials based on bioresources and to develop injection moulding procedures which enable a 100% circular economy with plastics. In total the #CDRSP team has been awarded in competition 77 days of beam time corresponding to over 7 months of continuous beam time. In 2025, the #CDRSP team plan to explore the potential of recently built beamline providing high resolution tomography and there is the possibility of real tomographic studies of injection moulding and other plastic processing. +INFO: link